Automated Food Plating System For Dinning Hall Details

Automated Food Plating System For Dinning Hall - Converyor Belt Control System

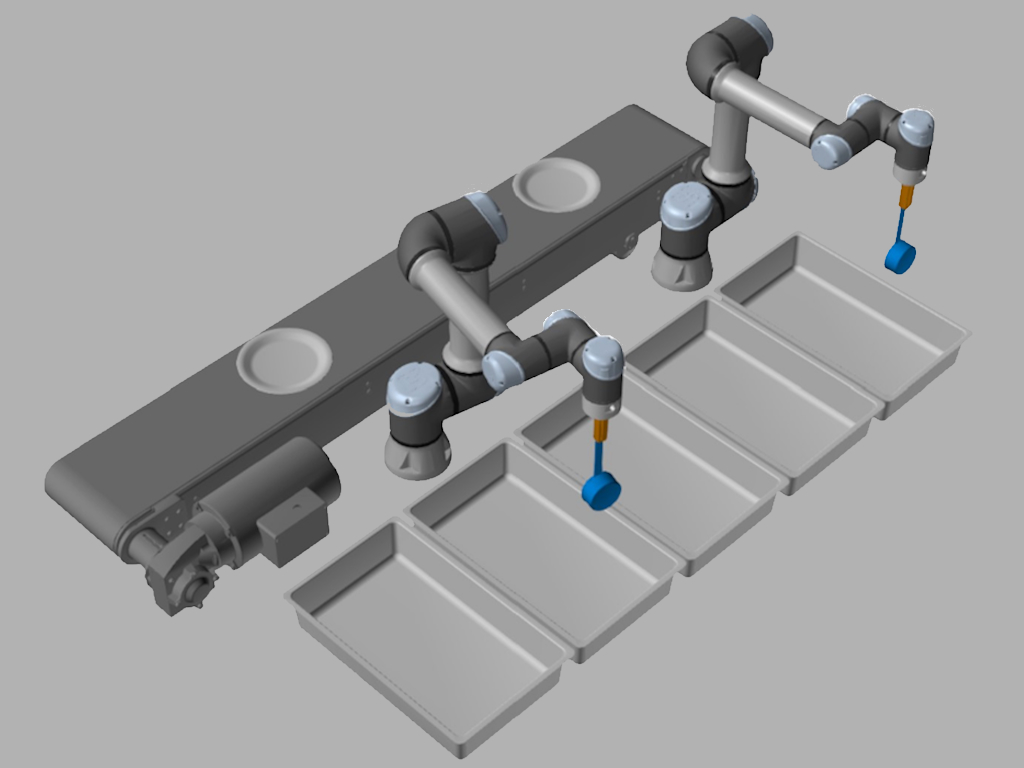

As part of a multidisciplinary capstone project, we developed an automated food plating system for the Commons Dining Hall. The goal was to streamline the food serving process using robotics and modular design, enhancing efficiency while reducing the need for manual labor. The system included multiple subsystems: a kiosk for order placement, a robotic arm for serving, a plate dispenser, and a conveyor belt to transport plates between stations.

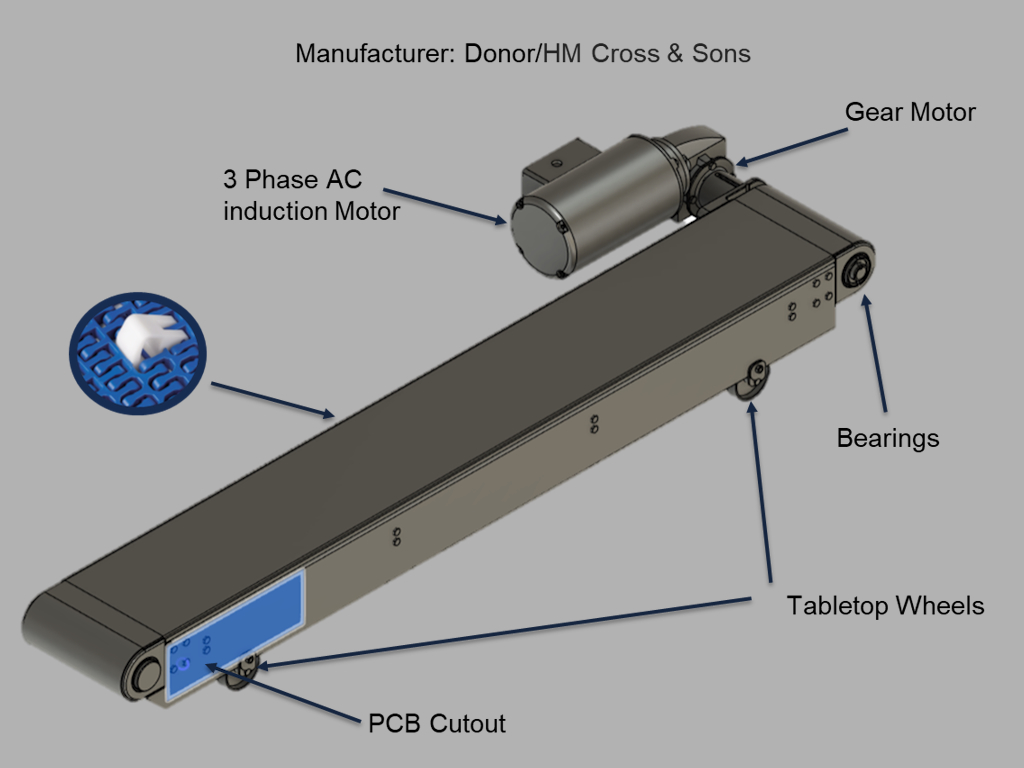

My primary contribution was the design and development of the Conveyor Belt Subsystem. This subsystem played a crucial role in ensuring the plates moved smoothly and accurately to each station, where different food items were served by the robotic arm.

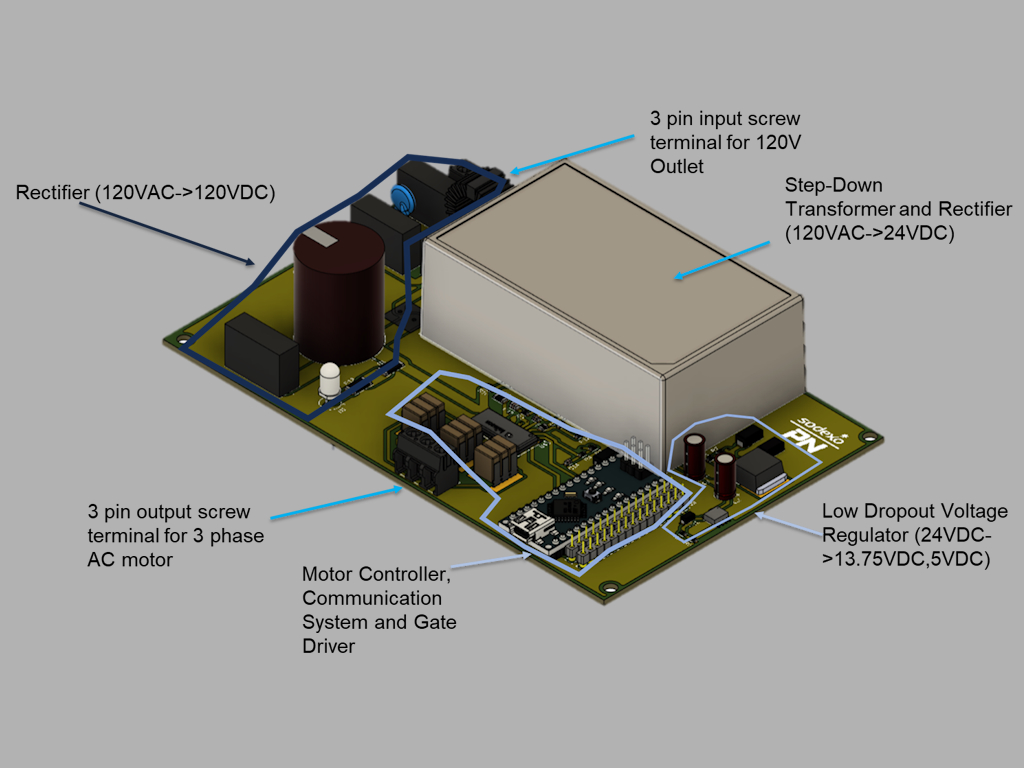

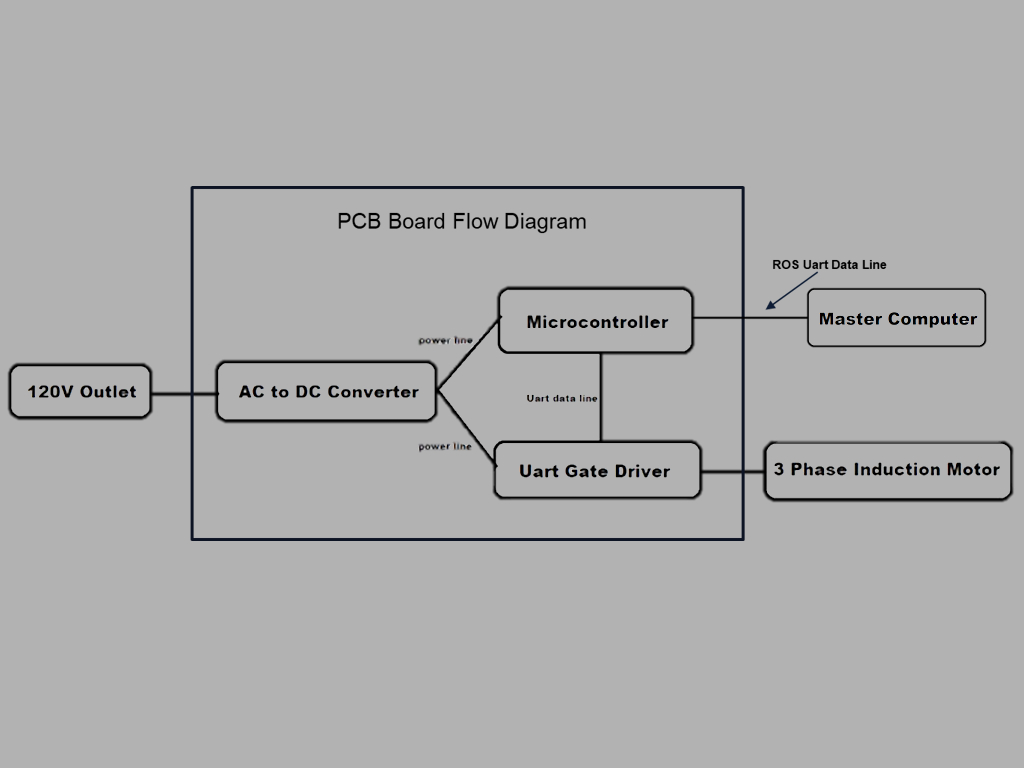

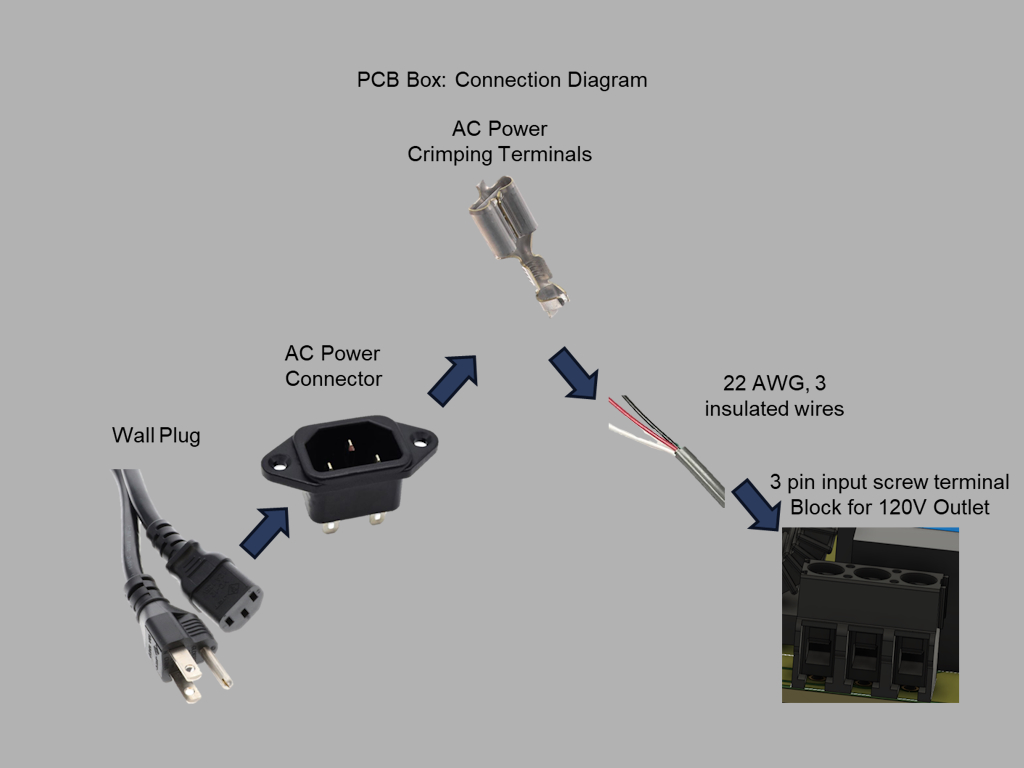

I was responsible for both the electrical and mechanical aspects of the conveyor belt. This included designing a custom circuit to control the motor's speed and direction, ensuring precise synchronization with other subsystems.

Due to the project's time constraints, I focused on creating detailed CAD models, initial code, and electrical schematics to facilitate the future prototyping stage. These resources were designed to make it easy for subsequent engineering groups to pick up where we left off. The next steps will involve physical testing and fine-tuning the motor speed. While the Conveyor Belt Subsystem was not physically prototyped, its design has been thoroughly prepared for seamless integration into the overall system.

Project information

- Category PCB Design/Control Systems/Software/Hardware

- Client Sedexo and Rensselaer Polytechnic Institute

- Project date 14 April, 2024

- Project PDF Download MEMO